By Richard Clough

Bloomberg News

It’s rarely a good sign when you become the butt of jokes.

But that’s what happened to Pratt & Whitney at an industry gathering recently, when John Leahy, the venerable chief salesman of Airbus Group, went on about a futuristic airplane — with an engine that “no doubt will be delivered late.”

While the audience was amused, Pratt surely wasn’t. It’s spent $10 billion and decades developing the quieter, more-efficient and less-polluting engine. Executives see the product as critical to catching up to rival General Electric in the market to power narrow-body planes, the dominant aircraft used by airlines around the world.

Instead, the engine’s debut has been marred by production delays, technical issues and supply-chain foul-ups. Qatar Airways last week cited the problems while announcing plans to buy planes powered exclusively by GE turbines. Pratt was forced to cut promised deliveries this year by 25 percent, frustrating some airlines and plane manufacturers counting on them. The troubles have dinged the stock of parent United Technologies Corp., as Pratt’s $14 billion in sales accounts for about one-quarter of its revenue.

“This is their big play to get back on single-aisles,” said Cai Von Rumohr, an analyst at Cowen & Co. “This is the one that’s going to have to happen if they’re going to be a player in large commercial engines.”

The company has characterized the production issues as “teething” problems typical to new technology. President Bob Leduc told Bloomberg in June that complaints were overblown, saying the engines in service have been reliable while meeting promises of 16 percent better fuel efficiency, 75 percent noise reduction and 50 percent less emissions.

“The engine is as we advertised, period,” he said. Pratt has about 8,200 orders for the product.

Founded in 1925, Pratt has a storied history, supplying engines to early planes and later for fighters in World War II. In the 1970s Pratt was the leader in selling engines for large passenger planes. But its position slipped in the 1980s when it miscalculated the market.

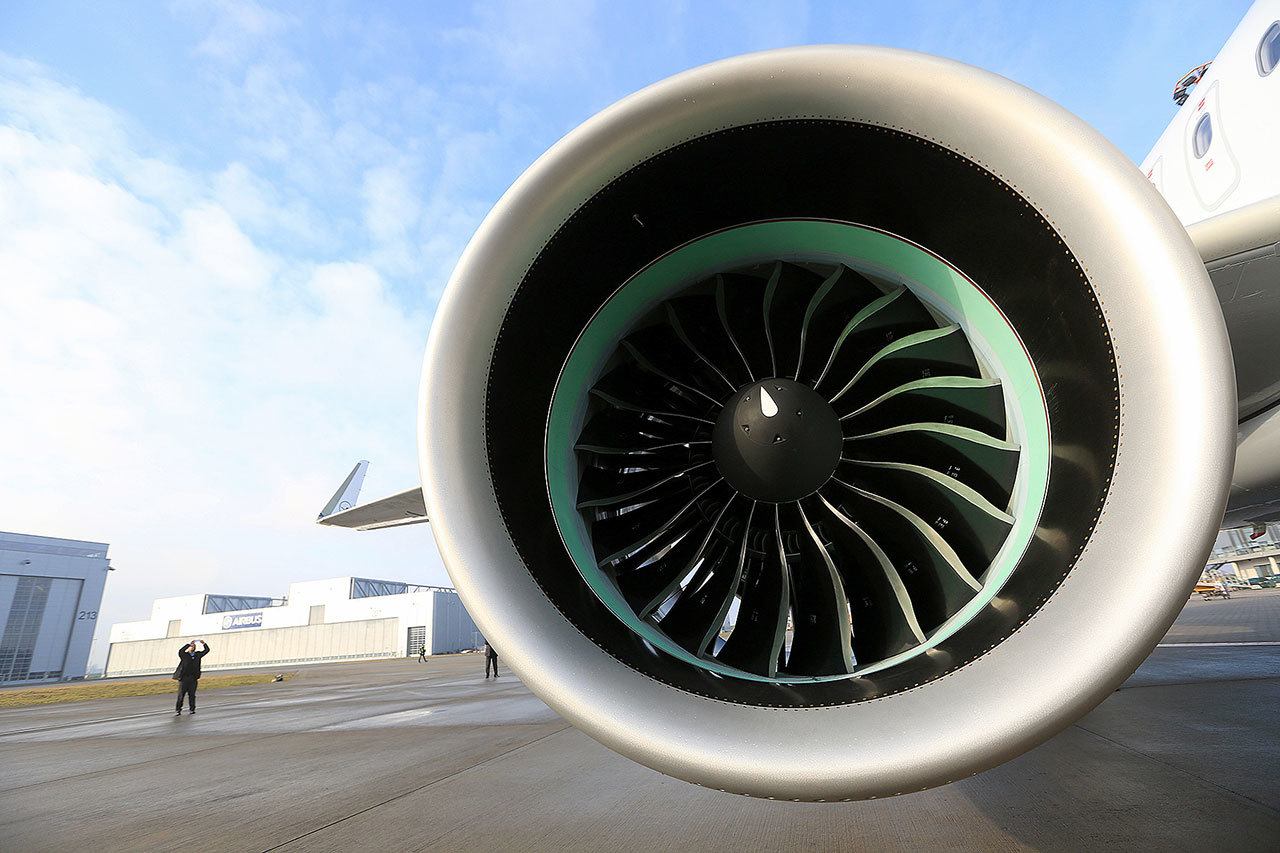

By the end of that decade, Pratt engineers began work on technology to slow the engine’s fan speed, which cuts noise and can improve efficiency. This year, the new engine, known as a geared turbofan, debuted in commercial service on the 180-seat Airbus A320neo (the “neo” standing for “new engine option”). Engine list price: more than $10 million apiece, say analysts.

But production issues led Pratt to revise its delivery schedule. Last month it said it would deliver only 150 engines this year, to planemakers such as Airbus and Bombardier, down from the 200 it had earlier pledged.

One of the sharpest blows came Oct. 7 when Qatar Airways made good on a threat to buy competitors to the A320neo over concerns about the delays. Chief Executive Officer Akbar Al Baker, a vocal critic of Pratt’s engine issues, said his carrier would order as many as 100 Boeing Co. 737 Max jets to “mitigate our risk” on the Airbus plane. He stressed the reliability of Boeing’s jet, which use engines from CFM International, a joint venture of GE and France’s Safran.

Pratt’s delays have forced Airbus to alter its delivery schedule, substituting 20 A320 jets with older engines in place of newer models, according to Douglas Harned, a Bernstein analyst. An Airbus representative said the company would hand over more older-version A320s this year “to make up for any shortfall on A320neo deliveries” but didn’t specify the number of planes.

The engine problems “appear significant with path to resolution currently unclear,” Harned wrote in a note. Pratt declined to discuss its plans to improve production processes.

Delays also forced Bombardier to halve projected 2016 deliveries of its marquee C Series jetliner. The company has a deal to use Pratt engines exclusively on the plane.

“This is very disappointing,” Alain Bellemare, Bombardier’s CEO, said in a speech.

But even after the various issues, Bellemare couldn’t muster bad words for the engine’s core technology: “I’m still very pleased that we made that choice. It’s the best engine available out there today for commercial aircraft.”

Pratt’s rivalry with GE remains fierce. GE’s Leap engine, the other option on the A320neo, debuted this year and achieves fuel savings largely through advanced materials. A320neo customers have picked GE’s engine about 54 percent of the time, and Pratt the rest, according to data from Ascend Flightglobal Consultancy.

More than one-third of A320neo orders have not announced an engine choice yet, leaving plenty of sales up for grabs.

The engine’s technical advances have contributed to some of the production problems. The aluminum-titanium fan blades are particularly complex, taking about 60 days to manufacture when they need to take half that time, Gregory Hayes, CEO of Farmington, Connecticut-based United Technologies, said in a presentation last month. The company is “still struggling to come down the learning curve,” he said.

The introduction of new technology is bound to have glitches, experts and industry leaders say. For that reason, Hungarian low-cost carrier Wizz Air intentionally scheduled deliveries several years down the line to allow time for kinks to be worked out, according to CEO Jozsef Varadi.

“I think by the time we start taking deliveries this will all get sorted,” he said in a recent interview. Wizz, which last year firmed up an order for 110 of the A321neo, targeted 2019 because “we don’t want to be associated with this mess.”

Pratt remains resolute, recently announcing plans to hire as many as 25,000 new workers in the next decade to work down the backlog. And joking aside, Airbus’s Leahy is standing behind the company.

“I have faith that Pratt will solve” the issues, he told reporters after poking fun at the engine delays. “It is disappointing the situation we find ourselves in, but it’s a good engine from everything we can see.”

Talk to us

> Give us your news tips.

> Send us a letter to the editor.

> More Herald contact information.